PVB A Comprehensive Analysis from Materials Science to Technological Applications

In this era of rapid technological advancement, the development and application of new materials have become a crucial driving force for progress. Polyvinyl butyral resin (PVB), as an exceptional polymer material, demonstrates tremendous potential across various fields. This article provides an in-depth exploration of PVB's chemical properties, production processes, and its extensive applications in modern technology, offering readers a comprehensive understanding of the scientific principles and technological appeal behind this remarkable material.

- Fundamental Characteristics of Polyvinyl Butyral

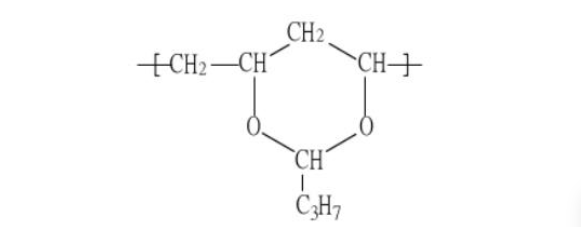

Polyvinyl butyral is a type of plastic made by combining polyvinyl alcohol and butyraldehyde. It boasts outstanding features including high transparency, excellent flexibility, and strong weather resistance.

- PVB Production Process Flow

1. Raw material preparation: Polyvinyl alcohol and n-butyraldehyde as primary materials;

2. Condensation reaction: Polyvinyl alcohol is dissolved in hot water with catalyst, followed by gradual addition of butyraldehyde solution to form PVB prepolymer;

3. Dehydration and drying: The obtained PVB prepolymer undergoes dehydration and drying processes;

4. Pelletizing and forming: Finally, the dried PVB powder is processed into desired shapes or specifications through extrusion and pelletizing techniques.

Application Fields of Polyvinyl Butyral

1. Automotive industry: PVB safety glass is great at preventing injuries from shattered glass and is often found in windshields;

2. Construction sector: PVB laminated glass makes windows safer, helps with insulation, and blocks noise, making homes cozier;

3. Electronics industry:Its strong adhesion and durability make PVB resin a good choice for different packaging and printing inks;

4. Packaging and printing: With excellent adhesion and wear resistance, PVB resin is suitable for various packaging coatings and printing inks.

Future Development Trends

Ongoing research focuses on optimizing PVB(PVB SD-1&PVB B-20HX)synthesis processes and expanding its applications. Environmental considerations have also made the development of biodegradable PVB a current research priority.

With its outstanding comprehensive performance, polyvinyl butyral is playing an increasingly vital role across multiple industries. As technology advances, we can confidently anticipate that PVB will continue to deliver more surprises and transformations.

Website: www.elephchem.com

Whatsapp: (+)86 13851435272

E-mail: admin@elephchem.com

Prev: Preparation and properties of modified PVA-CA blend ultrafiltration membrane